Computerized Frame Measurement (CFM) tools, despite misconceptions, enhance accuracy in car repairs by providing precise data and reducing human error. Skilled technicians leverage CFM for detailed body panel measurements, ensuring proper alignment and maintaining vehicles' structural integrity while fulfilling high quality and safety standards. While technology excels in detection, human expertise remains crucial for interpreting complex vehicle chassis interactions.

Uncover the truth behind prevalent myths surrounding computerized frame measurement, a game-changer in the construction and design industries. This article debunks common misconceptions about accuracy, challenges automated systems face, and explores real-world applications. We delve into the ongoing debate on human expertise’s role in the digital age, revealing why both approaches are essential for precise and reliable results in computerized frame measurement.

- Accurate vs. Automated: Debunking Precision Misconceptions

- Beyond Pixel Perfect: Real-World Applications

- Human Expertise: Still Relevant in Digital Age?

Accurate vs. Automated: Debunking Precision Misconceptions

Many believe that computerized frame measurement (CFM) tools are only capable of providing automated precision, but this isn’t entirely true. While CFM systems offer a level of automation, they do not sacrifice accuracy. In fact, these advanced technologies are designed to enhance measurement capabilities and ensure precise results. Unlike manual methods, which can be subjective and time-consuming, CFM systems use sophisticated algorithms and sensors to capture intricate data points, resulting in highly accurate frame measurements.

One common misconception is that automated processes introduce errors. However, when utilized correctly, CFM tools can reduce human error significantly. These systems are calibrated regularly and designed to provide consistent, repeatable results. In the context of fleet repair services or an automotive body shop dealing with hail damage repair, relying on CFM ensures that each vehicle undergoes precise assessments, leading to more effective repairs and higher customer satisfaction.

Beyond Pixel Perfect: Real-World Applications

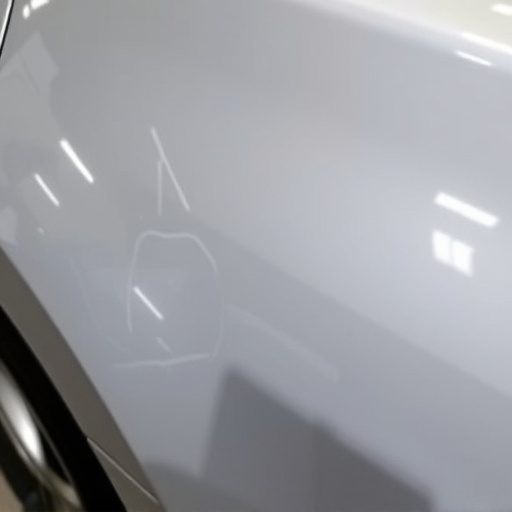

While pixel perfection is often the goal in digital imaging, computerized frame measurement goes beyond mere aesthetics. In real-world applications like car repair services and car bodywork, precision is paramount. Computerized systems aren’t just about capturing flawless images; they enable highly skilled technicians to analyze and diagnose car damage repair with unprecedented accuracy.

These tools allow for detailed measurements of car body panels, ensuring that every component is aligned correctly during the repair process. This goes beyond what human measurement alone can achieve, leading to more precise, faster, and effective car damage repair. The benefits extend to maintaining the original look and feel of the vehicle’s bodywork, ensuring it returns to its pre-damage state.

Human Expertise: Still Relevant in Digital Age?

In the digital age, where technology promises precision and efficiency, one might question the role of human expertise in fields like computerized frame measurement. After all, advanced software and sensors are designed to detect even the slightest deviations in vehicle frames with remarkable accuracy. However, while computerized frame measurement tools have undoubtedly enhanced the process, they don’t replace the invaluable skills and insights of trained technicians. Human experts remain an integral part of collision repair services and auto body repair, ensuring that every vehicle is assessed holistically.

Consider that human eyes can detect subtle nuances in frame alignment that might be missed by digital instruments. Moreover, experienced technicians understand the intricate relationships between various components of a vehicle’s chassis, allowing them to interpret data from computerized frame measurement systems with greater context. This blend of advanced technology and human expertise ensures that automotive repair services remain at the forefront of precision and safety, guaranteeing that every repaired vehicle meets the highest standards of quality and structural integrity.

Computerized frame measurement has evolved, challenging traditional notions of precision and human expertise. While automation offers speed and efficiency, it doesn’t replace the nuanced understanding that human professionals bring. In reality, computerized systems excel at repetitive tasks, but human experts remain invaluable for complex projects requiring creative problem-solving. Thus, embracing a blend of automated technology and skilled manpower ensures optimal results in various industries, leveraging the strengths of both while dispelling myths along the way.