Computerized frame measurement is transforming auto body shops by offering unprecedented precision and efficiency compared to manual methods. This technology enables quick and accurate measurements using specialized equipment, aiding in complex tasks like aligning panels and ensuring precise fitting. The detailed data empowers technicians to make confident adjustments, delivering superior craftsmanship and enhanced customer satisfaction, while modernizing operations and gaining a competitive edge in today's market.

Frame repair shops are embracing the future by investing in computerized frame measurement technology. This innovative approach revolutionizes traditional methods, enhancing accuracy and efficiency in repairing vehicles. By adopting this tech, shops can offer more profitable services, reduce labor costs, and streamline processes. Computerized frame measurement benefits include precise damage assessments, faster turnaround times, and improved customer satisfaction. Embrace this modernization drive for a competitive edge in the automotive repair industry.

- Enhancing Accuracy: Computerized Frame Measurement Benefits

- Modernization Drive: Adopting Tech for Profitable Repairs

- Streamlined Processes: Boosting Efficiency with Computerized Tools

Enhancing Accuracy: Computerized Frame Measurement Benefits

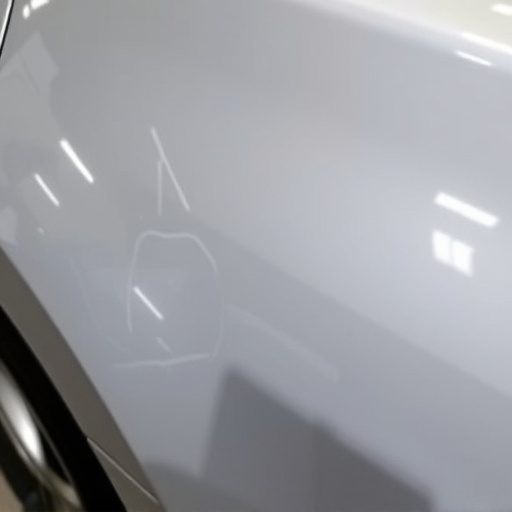

Computerized frame measurement is transforming the way auto body shops, particularly those specializing in frame repair, conduct their business. This advanced technology offers a significant leap forward in terms of precision and efficiency compared to manual methods. By utilizing specialized equipment that scans and analyzes a vehicle’s frame, these shops can now obtain highly accurate measurements in a fraction of the time.

This innovation is especially beneficial for complex tasks such as aligning panels after dent removal or ensuring precise fitting during automotive repair services and car paint services. The system provides detailed data on frame deformations, enabling technicians to make minute adjustments with confidence, ultimately resulting in superior craftsmanship and customer satisfaction.

Modernization Drive: Adopting Tech for Profitable Repairs

In today’s competitive market, frame repair shops are feeling the pressure to modernize and stay profitable. One area where they’re investing heavily is in computerized frame measurement technology. This shift is driven by a need to enhance precision and efficiency in car body repair services. Traditional methods often relied on manual measurements, which could be time-consuming and prone to human error. With computerized systems, repairs become faster and more accurate, allowing shops to take on more complex jobs and maintain higher standards of quality.

By embracing this tech, frame repair shops are not only improving their operational capabilities but also gaining a competitive edge. Car bodywork services that once struggled with laborious tasks can now offer faster turnaround times, reduce waste, and provide customers with transparent estimates. This modernization is especially beneficial for smaller workshops looking to compete with larger, more established businesses offering advanced car repair services.

Streamlined Processes: Boosting Efficiency with Computerized Tools

In today’s competitive auto body services market, investing in computerized frame measurement tools is a game-changer for repair shops offering vehicle body repair and car bodywork services. These advanced systems streamline processes, ensuring precise measurements and faster turnaround times. By automating what was once a manual and time-consuming task, shops can boost efficiency, reduce human error, and provide customers with more accurate quotes.

Computerized frame measurement technology plays a crucial role in modern auto body repair shops, enabling professionals to perform detailed assessments quickly. This not only enhances the overall customer experience but also contributes to the shop’s bottom line by optimizing labor costs and minimizing waste. With precise data on hand, technicians can make informed decisions, ensuring every car bodywork job is executed with precision and efficiency.

The investment in computerized frame measurement technology is a strategic move for frame repair shops to stay competitive and efficient. By enhancing accuracy, modernizing their approach, and streamlining processes, these shops can deliver higher-quality repairs, reduce waste, and ultimately improve profitability. Computerized frame measurement is not just a trend but an essential tool for staying ahead in the automotive repair industry.